Iso-Slurry Management System

We are pleased to introduce the Iso-Slurry Management System to add to our current range of Slurry products.

The Iso-Slurry fully integrates into the ISOBUS system available in most modern tractors. The equipment has been designed as a ‘plug and play’ unit utilising existing equipment.

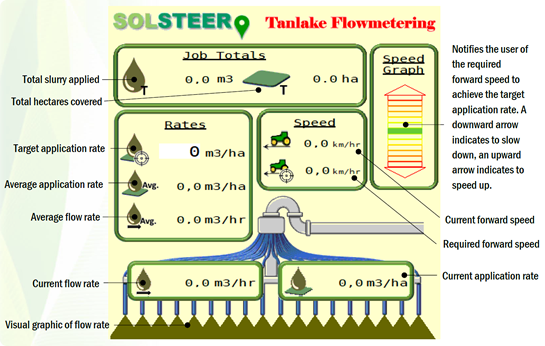

Shown below is an example of the information available to the Operator.

No modifications are needed to the tractor.

Wiring Loom and Iso-Slurry Module is all that is needed to connect to the ISOBUS

On set-up this is the Home page that will be shown.

Successful Trials have been carried out and customer comments are shown below:

Charles, Farm Manager and Grosvenor Farms has been working with Tim Hodkinson from Cornthwaite Group, to assist in the accurate application of manure on their Cheshire farms.

- Why you had an interest in that type of system?

- Integration into farm management software, accurate records of daily application amounts, coupled with sampling for as applied maps that can then inform subsequent applications, so variable rate fertilizer spreader can follow with top-up applications. We required something affordable and as seamless as possible into an existing software solution (JD Op centre)

- How it helps you manage your business?

- Seamless transition to record keeping on a field by field basis saving on admin . Also really easy recording on changes and tweaks to the system, e.g. booster pumps, pipe size changes, i.e. techniques for extra flow. Gives the guys on the job targets to meet and beat.

- How it helps you manage your manure?

- Can plan on a field by field nutrient management plan, increasing or maintaining indices and applying the right amount of N depending on the crop. This then pushes the application map wirelessly back to the farm office via the JD link terminal on the tractor.

- Benefits to you as a business?

- All of the above really. For me, and it’s a very simple point, the biggest change has been the staff buy in, the display and recording of the flow rates etc has had a really quick and simple motivator. The other points are simplifying the transition of records, ability to create vary rate maps from the as applied maps and record keeping.

You wouldn’t expect a former police officer to have a background that would now benefit contractors and large farms managing slurry and biogas digestate. But with his forensic skills and determination, John Burnham, the man behind Tanlake Flowmetering, has grown what was a small ‘cottage’ industry into a concern where his flow measurement equipment and software is now fitted to a large number of slurry application machines, not just in the UK, but around the world.

You wouldn’t expect a former police officer to have a background that would now benefit contractors and large farms managing slurry and biogas digestate. But with his forensic skills and determination, John Burnham, the man behind Tanlake Flowmetering, has grown what was a small ‘cottage’ industry into a concern where his flow measurement equipment and software is now fitted to a large number of slurry application machines, not just in the UK, but around the world. On 22nd July we were pleased to welcome Jacob Rees-Mogg MP for North East Somerset.

On 22nd July we were pleased to welcome Jacob Rees-Mogg MP for North East Somerset.

Tanlake is part of this process and in combination with better and more technologically innovative tractors fields can be mapped and then fertilised with great precision. This helps improve soil quality, saves costs and boosts productivity.

Tanlake is part of this process and in combination with better and more technologically innovative tractors fields can be mapped and then fertilised with great precision. This helps improve soil quality, saves costs and boosts productivity.